The Impact of American-Made Product Manufacturers

Posted by STI-CO® Antenna Solutions on 17th Jul 2023

When sourcing components, parts or finished products for your business, you’re searching in a global marketplace. Amid all the suppliers available, manufacturers of products made in the U.S. play a significant role in providing buyers with high-quality products that provide dependable service.

In this blog, we will be answering these questions:

- What are the key characteristics of American-made manufactured products?

- How have American manufacturing processes and technologies evolved over time?

- What are some of the challenges facing American manufacturers?

- How does American manufacturing compare to manufacturing in other countries in terms of quality, cost, and efficiency?

- What impact does government policy have on American manufacturing?

- What are some of the trends and innovations currently shaping the American manufacturing industry?

What are the key characteristics of American-made manufactured products?

American manufacturing is focused on research and development, which plays a significant role in incorporating the latest advancements into products and manufacturing processes. This emphasis results in several attributes that define American-made products.

- High-quality finished products made of premium materials

- Strict quality control procedures and standards

- Constant innovation of products, processes, and systems

- Customization of products for specific applications and industry sectors

- Reliability and durability for long-term performance

- Manufacturing that complies with labor and environmental standards.

The ultimate objective of American manufacturing is to create high-quality products that fulfill customers' needs. Achieving this involves using the best materials, adhering to stringent standards, implementing top-notch manufacturing practices, and design.

How have American manufacturing processes and technologies evolved over time?

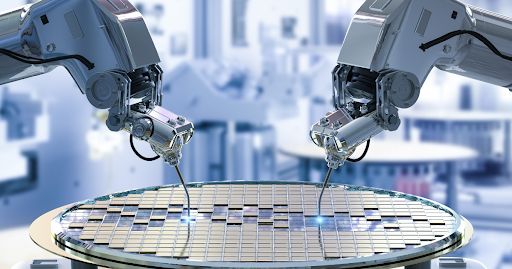

Twenty-first century manufacturing facilities are much different than those in use just 50 years ago. Historically, manufacturing relied extensively upon manual labor, large numbers of workers, and traditional methods. Many steps in the manufacturing process demanded the dexterity of the human hand to produce complex and intricate assemblies or to precisely place components at each step.

Changes in manufacturing power, factory operation, and a wide range of technologies have altered the production process. From assembly-line methods to conveyor systems and automation, scientific and technical innovations have improved working conditions and efficiency in manufacturing.

Automation technology and computer-controlled systems have increased efficiency, production volume and repeatability, leading to higher quality as well. For example, automated and robotic technologies are used now in producing cable kits that years ago had been made by hand. Today these kits are made more rapidly and meet a range of specifications with precision and efficiency, and even higher levels of quality control.

What are some of the challenges facing American manufacturers?

Every industry must address various external and internal pressures in order to remain viable. Today, American manufacturing faces challenges including global competition, cost pressures, supply chain disruptions, and the workforce skills gap.

Global Competition

In today’s interconnected world, goods can be sourced from anywhere. The competition is fierce, and price is often a determining factor. However, price alone doesn’t define all the requirements from a supplier. Product availability, quality and performance must be considered as well. It’s also important to note shipping costs and lead time, both of which may increase when suppliers are located overseas.

Cost Pressures

Rising costs of raw and processed materials and labor are a challenge for today’s manufacturers. Manufacturers address these challenges by focusing on lean manufacturing practices that minimize waste and emphasize a wise use of available resources. Additionally, there is a constant focus on innovation in methods and materials to help contain costs.

Supply Chain Disruptions

Recent years have brought extensive disruption to supply chains throughout the world and caused many manufacturers to reconsider their practices. However, disruptions have not affected manufacturers equally. Some are able to rely on their own internal capabilities for in-house production and can work with local suppliers, but even so, they may be affected by disruptions that affect their customers and the components and products they provide.

Workforce Skills Gap

Many industries are seeing a gap in the availability of trained, skilled workers to meet their hiring needs and keep facilities fully operational. In response, many manufacturers are involved in workforce development activities to help train new workers and close the skills gap. At the same time, robotics and automation technologies are helping manufacturers to handle certain operations to help maintain full production.

How does American manufacturing compare to manufacturing in other countries in terms of quality, cost, and efficiency?

Cost, quality, and efficiency are some of the key considerations when comparing American manufacturers with offshore suppliers These reasons, among others, are why customers choose American made products.

In general, American manufacturers have a reputation for higher quality products at a higher price point. Working with an American supplier offers additional benefits including:

- Increased innovation based on investments in research and development.

- Sustained dependable quality for the customer, using advanced methods for accuracy and speed.

- Greater speed of delivery through shorter lead times, and increased efficiency.

- Easier collaboration when manufacturer and supplier are geographically closer, particularly for custom products.

- More immediate communication because customer and supplier are separated by fewer time zones.

- Less subject to disruptions connected with overseas shipping and associated costs.

Along with these advantages, product quality is a critical strength of U.S. manufacturing that contributes to customer satisfaction. Certifications compliance with ISO Certification 9001: 2015provide assurance of quality and dependable product performance.

What impact does government policy have on American manufacturing?

Government policy sets out various guidelines for procurement practices related to the origin of products purchased for specific applications. These include legislation and specific administration:

- Buy American Act: The U.S. Government Accountability Office describes this act as one that requires Federal agencies to procure domestic materials and products under specific circumstances, including public use within the United States.

- Build America Buy America Act: This act went into effect in 2021 as part of the Infrastructure Investment and Jobs Act. It requires a domestic content preference for procurement of U.S. manufactured products and building materials for certain infrastructure projects in the U.S.

- Made in America Office: designs policies to increase reliance on domestic supply chains and promote the procurement of American-made products when tax dollars are being spent, and supports application of related legislation.

Through these and other initiatives, trade policy regulations and incentives strive to strengthen and support the American manufacturing industry as a whole.

What are some of the trends and innovations currently shaping the American manufacturing industry?

Many different advancements in manufacturing have grown from the widespread increases in computer technology, enhanced computational power, and advanced technology. The widespread growth of computer technology, increased computational power, and advanced technology has fostered numerous advancements in manufacturing. These developments enable manufacturers to work smarter rather than harder, leading to new methods and products.

Automation and robotics introduced into the production system relieve workers of many repetitive tasks and enhance the speed and efficiency of many operations. Increased production volume and improved quality are often additional benefits of automation.

Computer aided design (CAD) has transformed the design process from a labor-intensive task to one that operates at the speed of innovation. Changes can be documented and implemented quickly, and a comprehensive record supports all project stages.

Data analytics has come to the forefront with high speed computing processes. As a result, raw data can be captured and analyzed to improve quality, address process bottlenecks, and guide decision making.

Additive manufacturing, especially 3D printing, has provided manufacturers with the ability to rapidly create prototypes which, in turn, greatly speeds the time from design to production.

Summary

Staying competitive in the global market requires American manufacturers to stay updated on trends and innovations.

Customers have a multitude of choices, and their purchasing decisions are influenced by various criteria. In this landscape, American manufacturers, especially those serving domestic entities, play a crucial role in delivering the quality and performance that customers demand.

If you have any questions or need assistance in finding the right antenna solution, please contact STI-CO® Support at 866-307-8426, email us at sales@sti-co.com, or visit our website at www.sti-co.com. You can also explore additional resources on our blog.